What is the...?

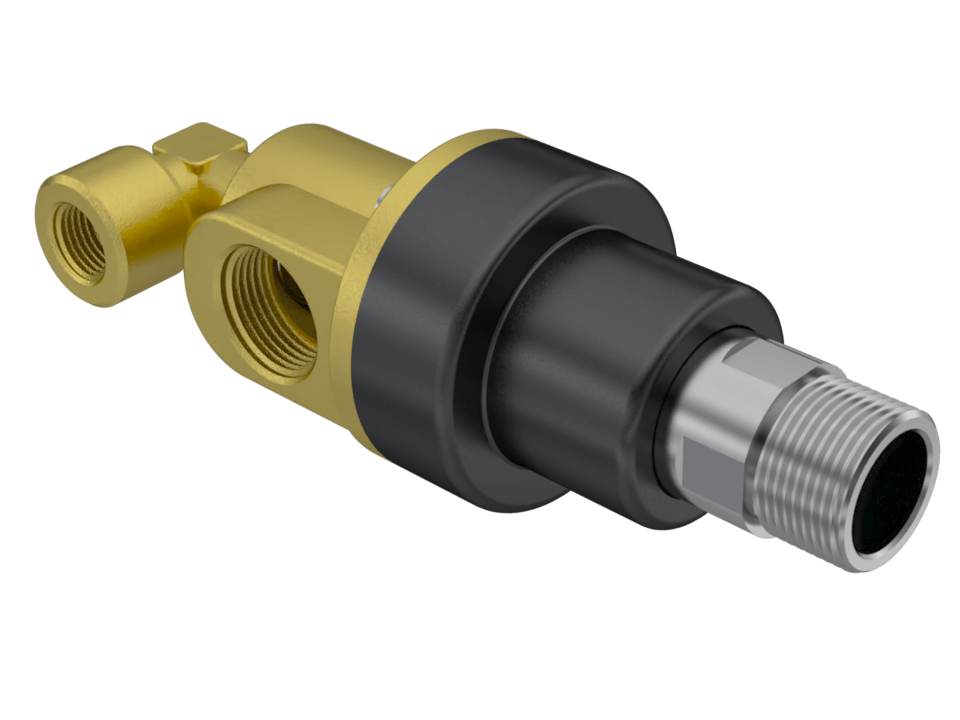

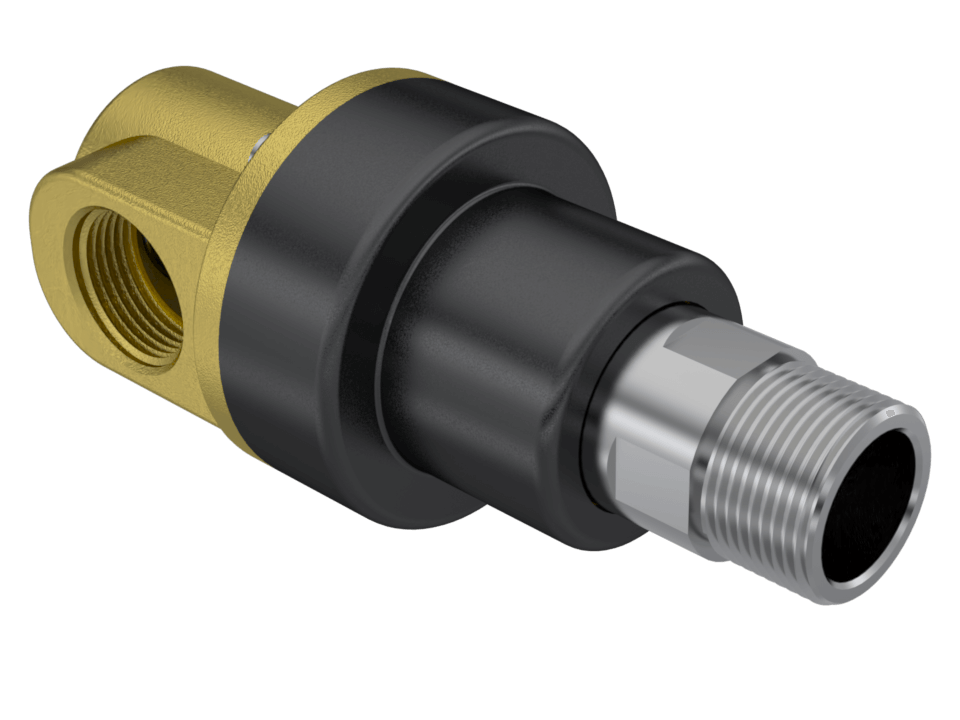

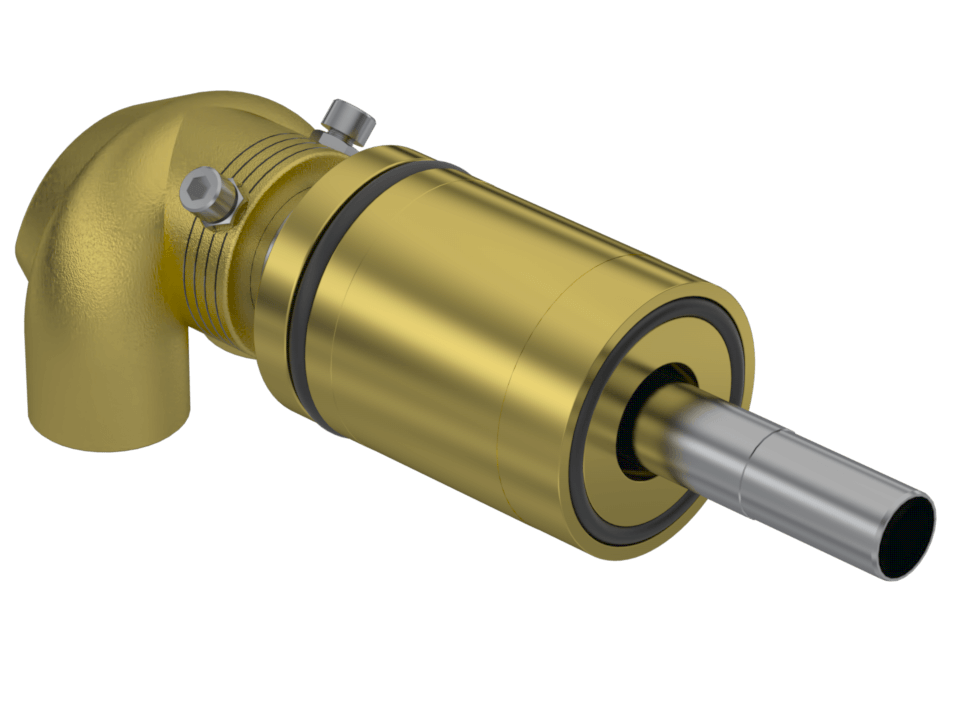

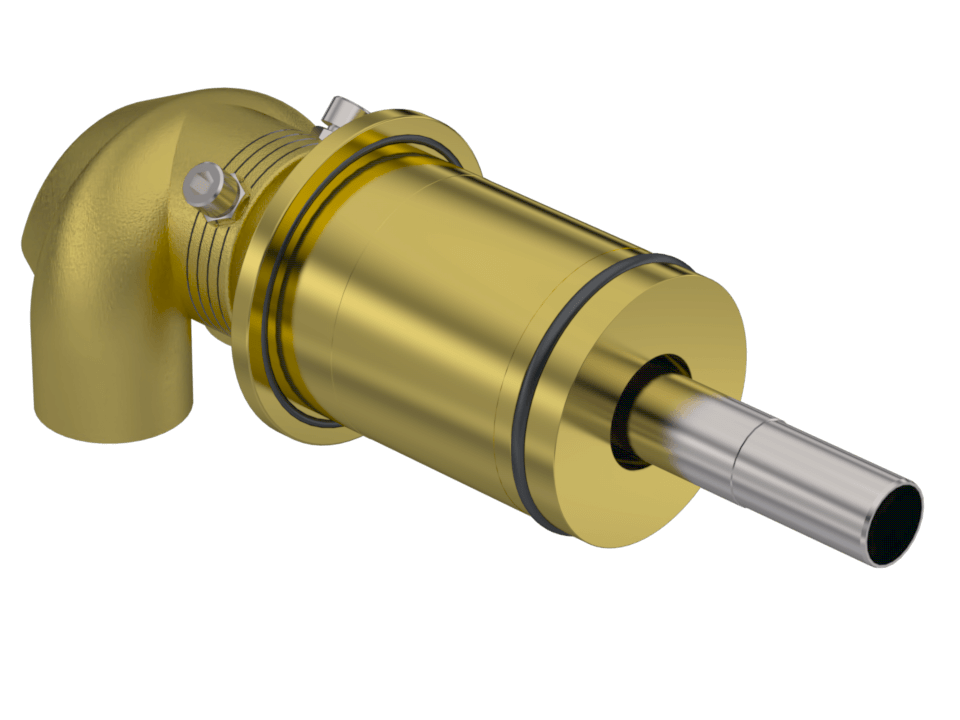

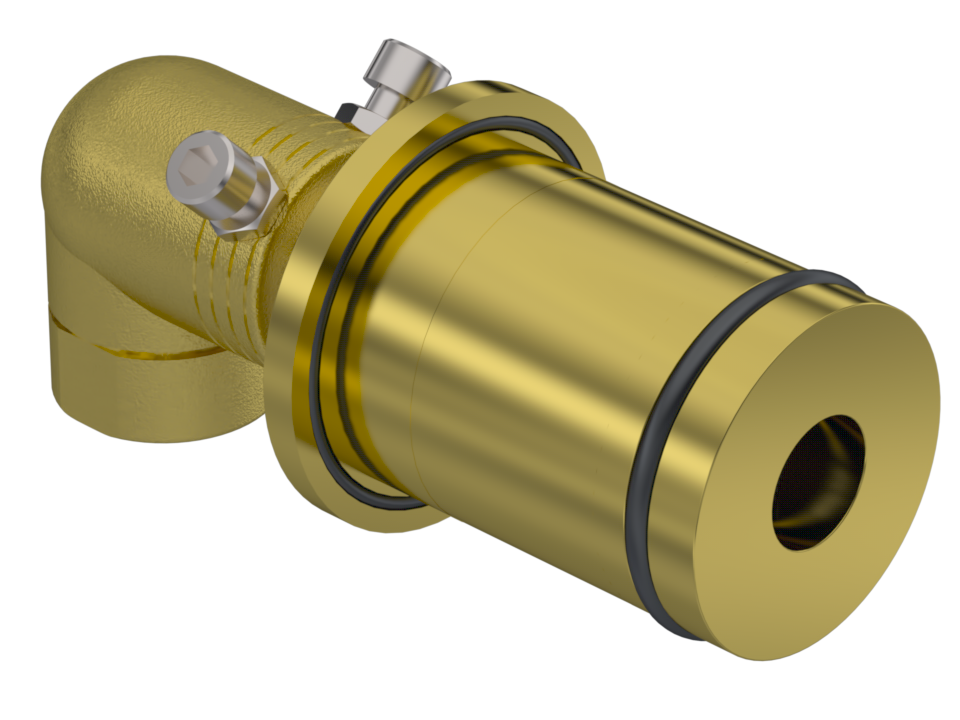

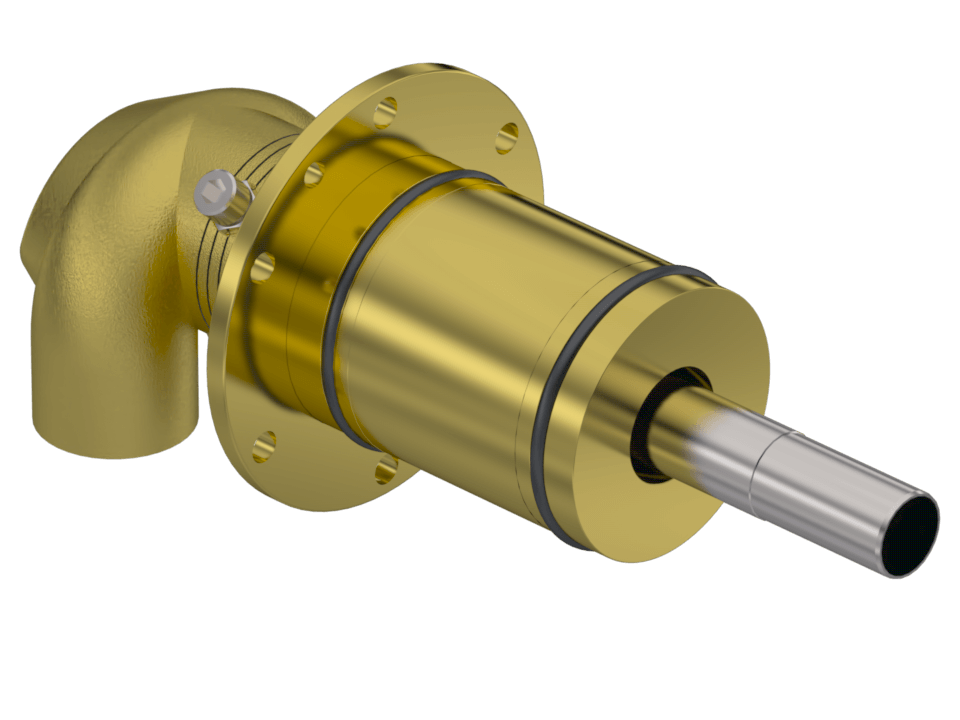

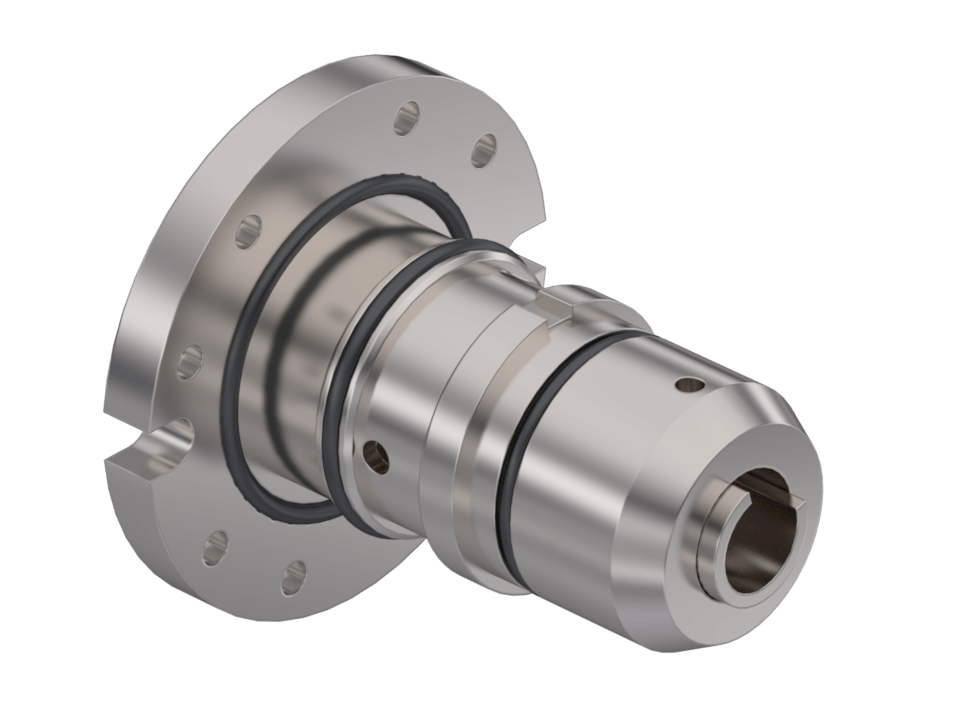

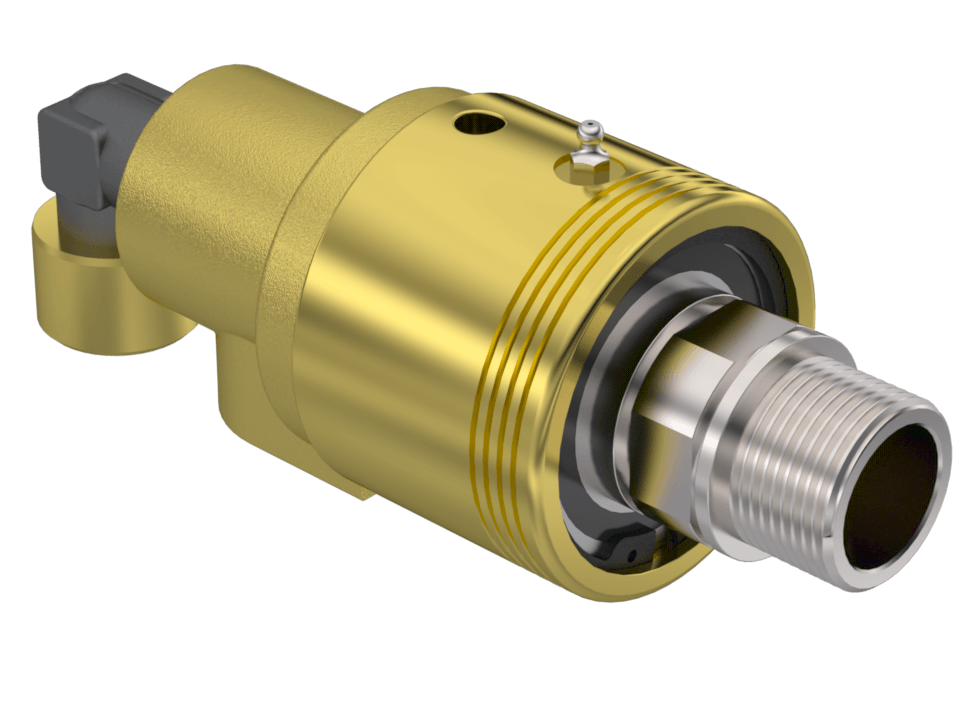

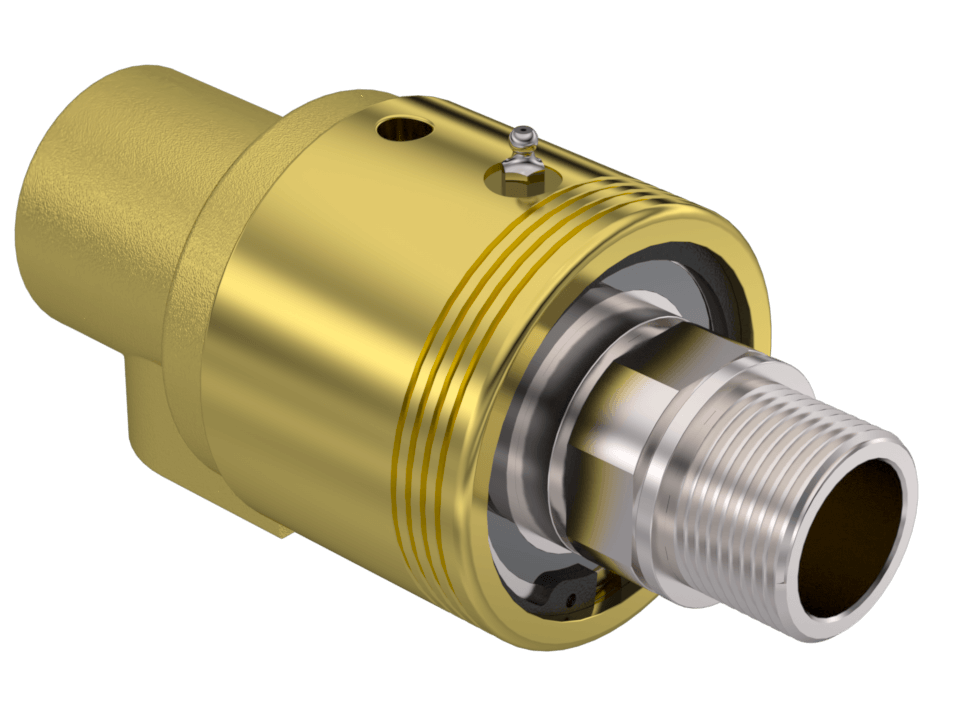

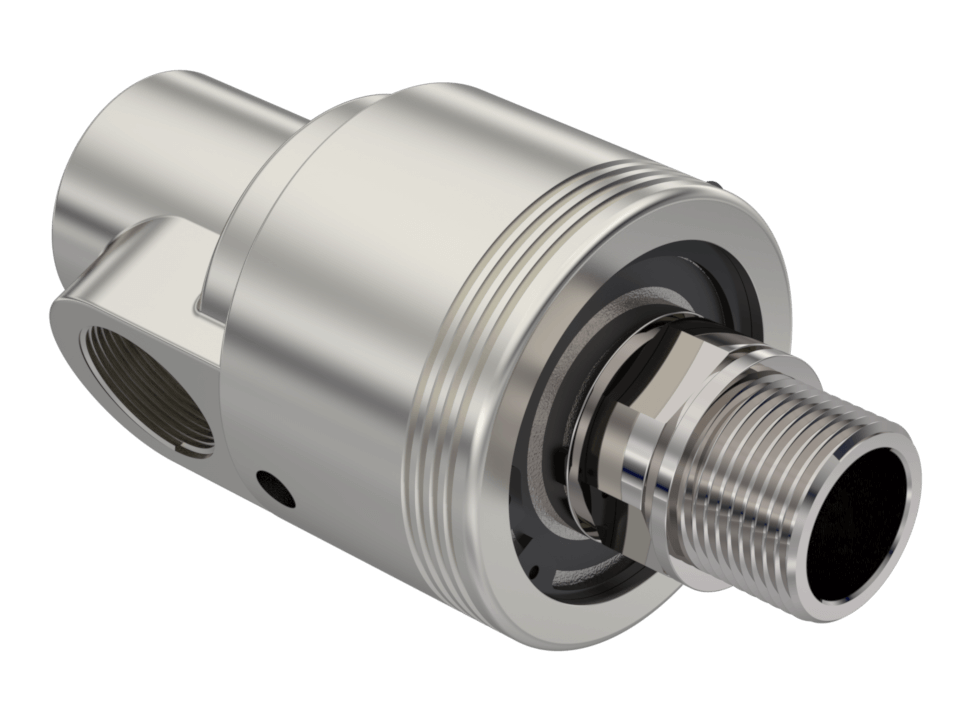

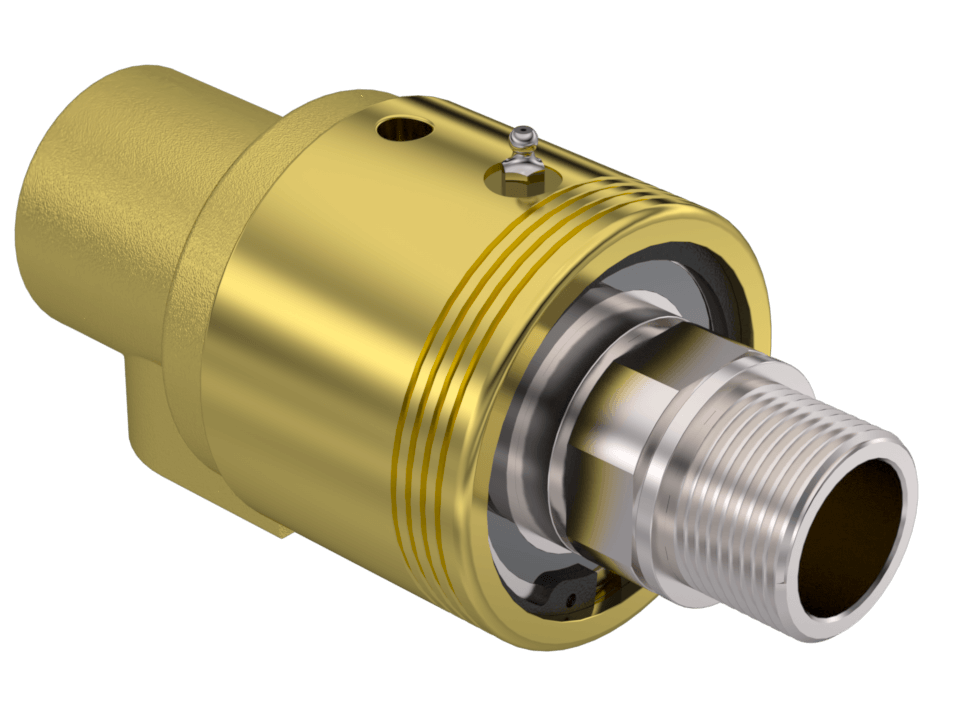

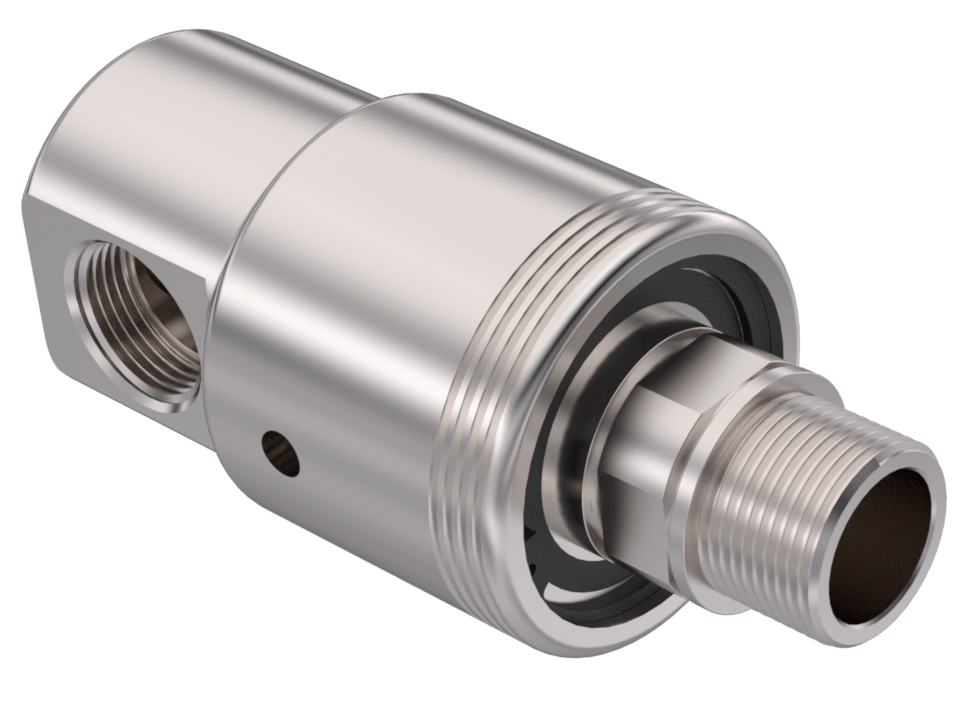

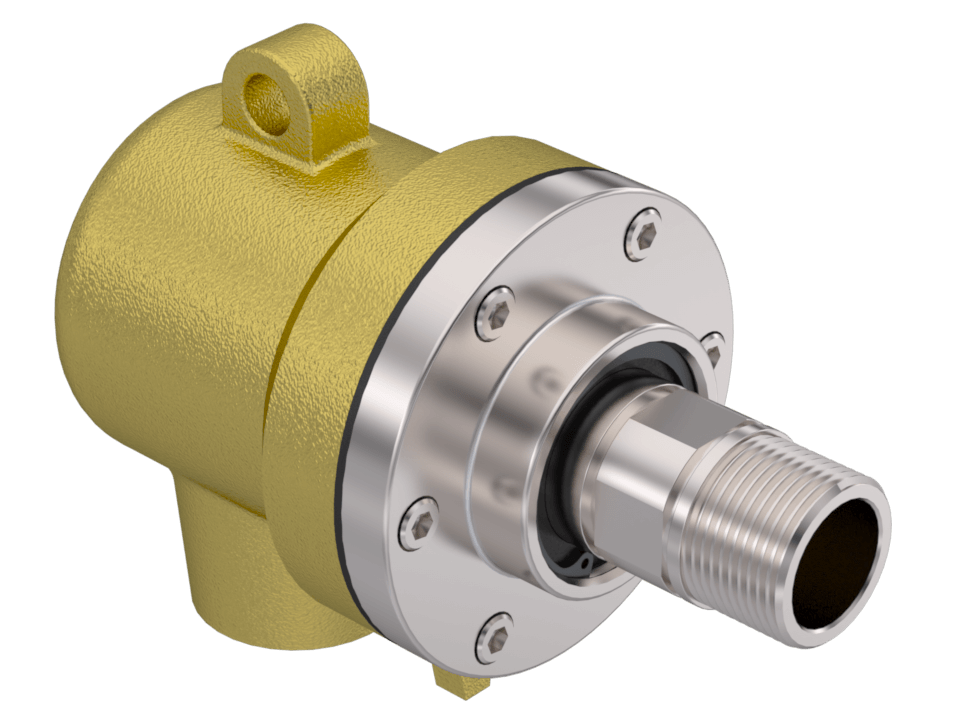

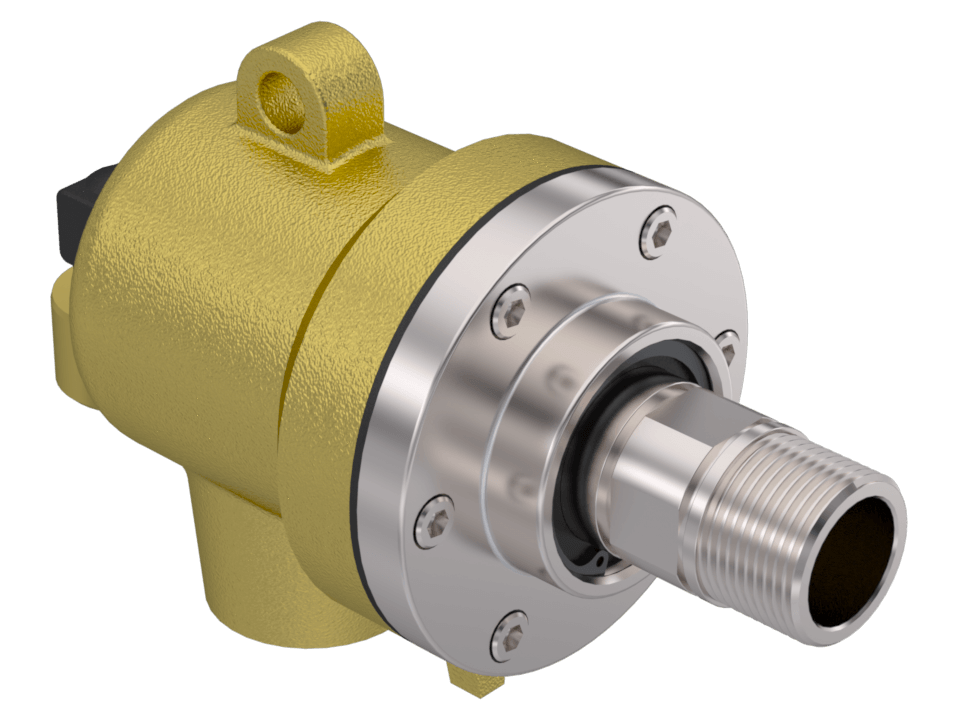

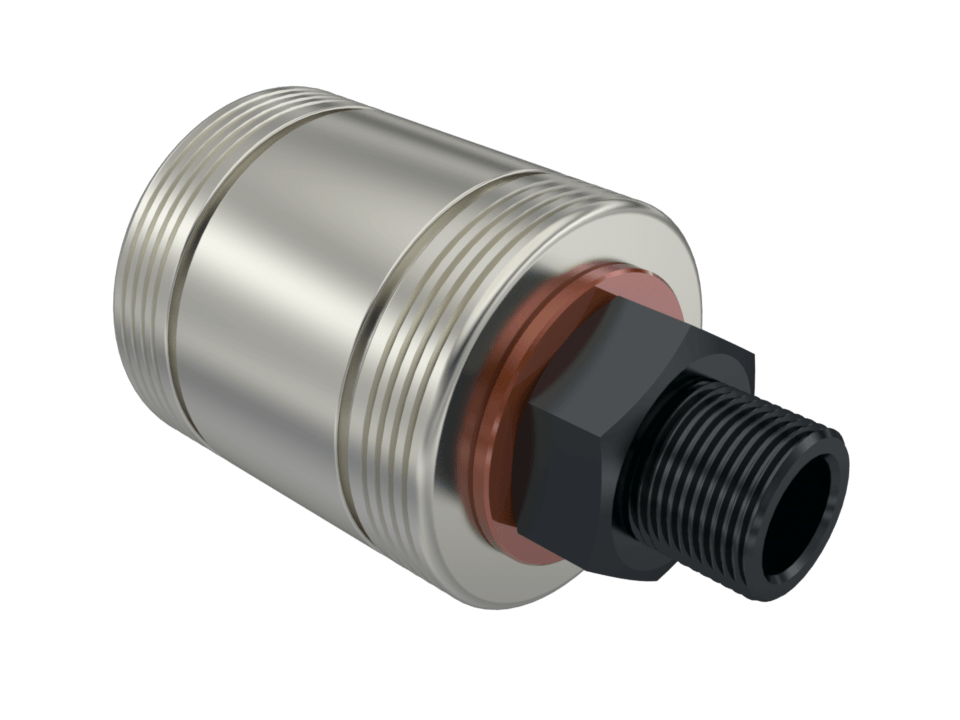

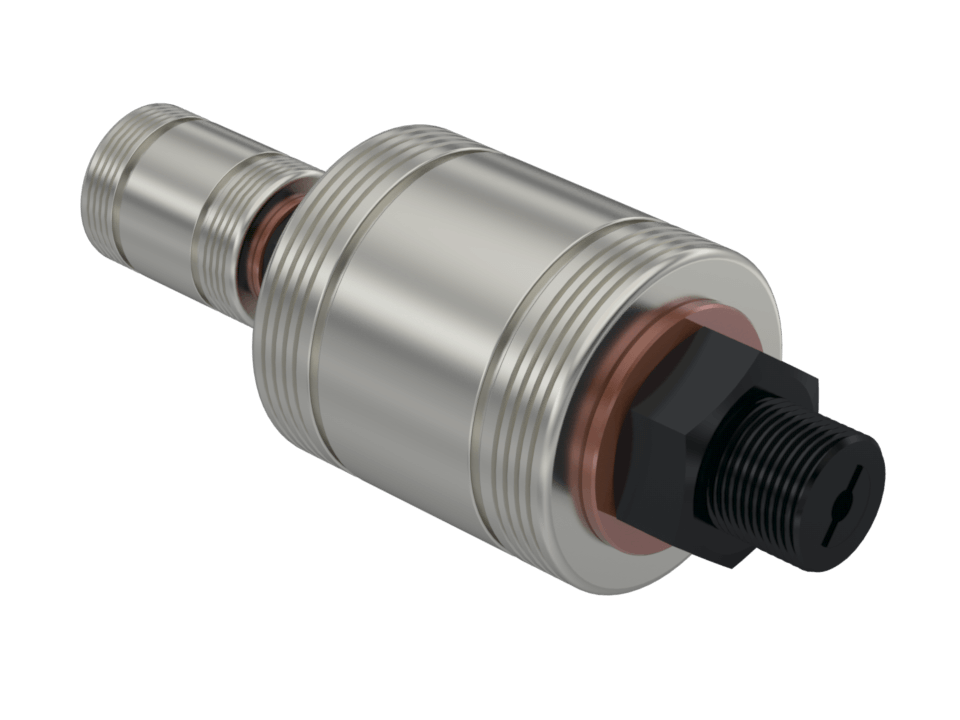

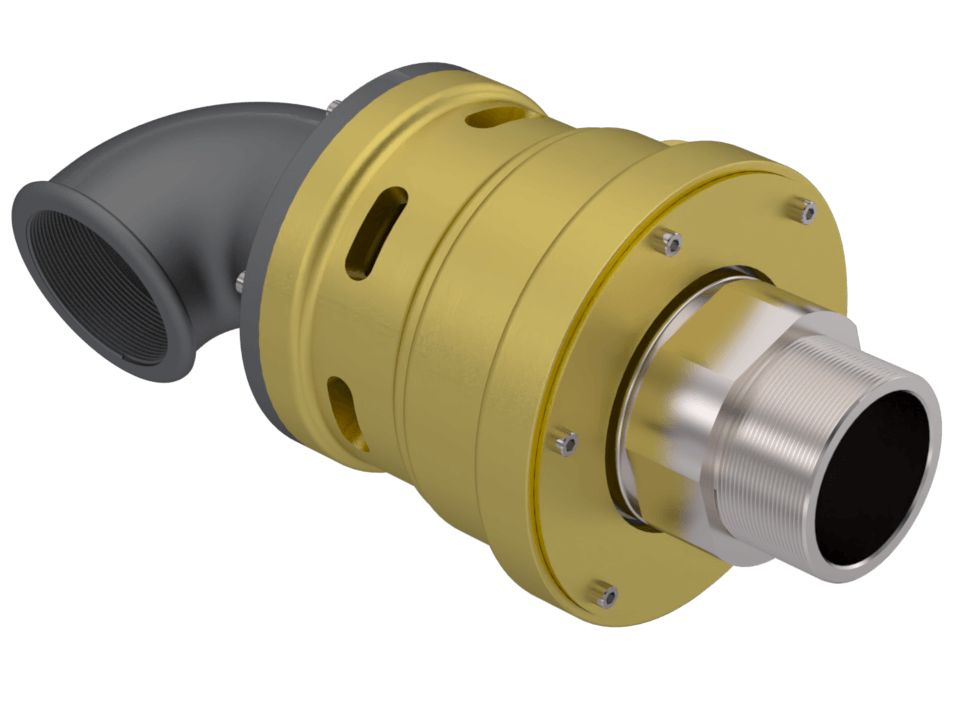

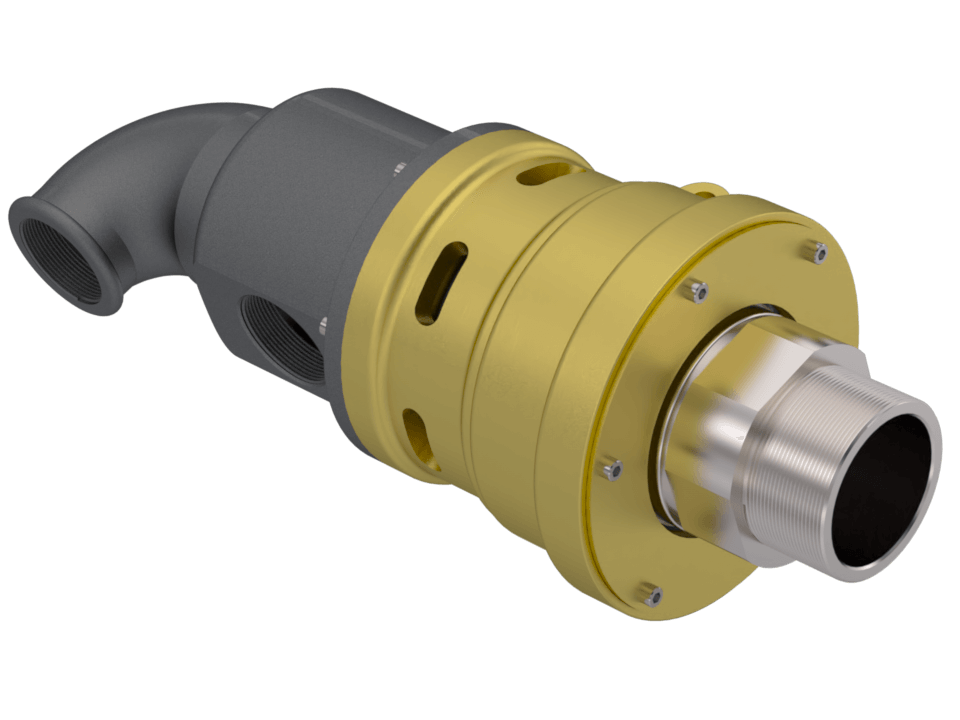

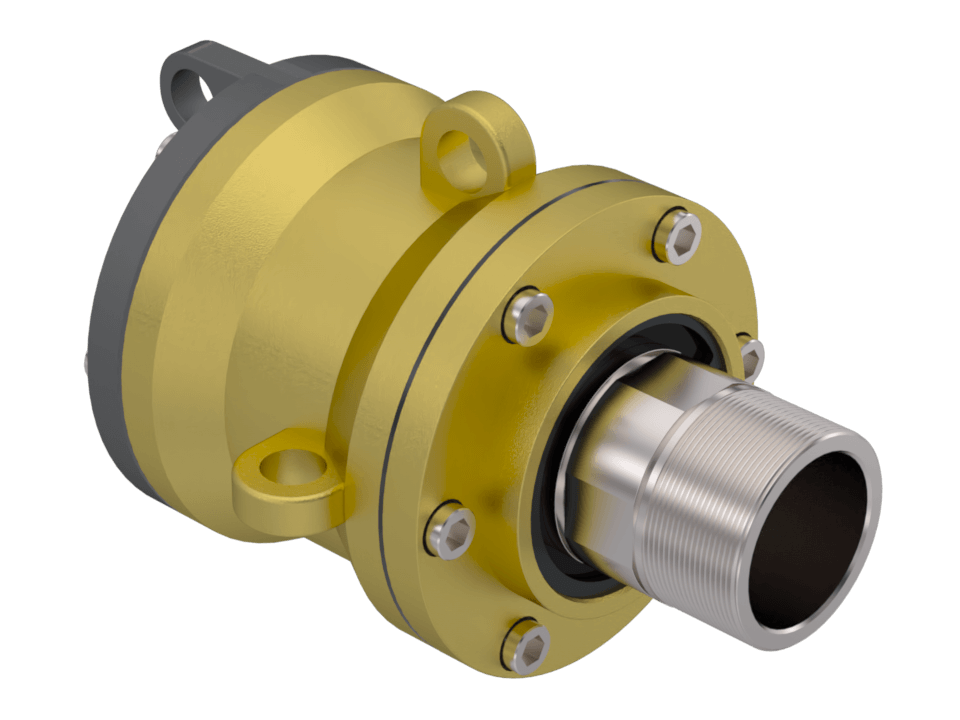

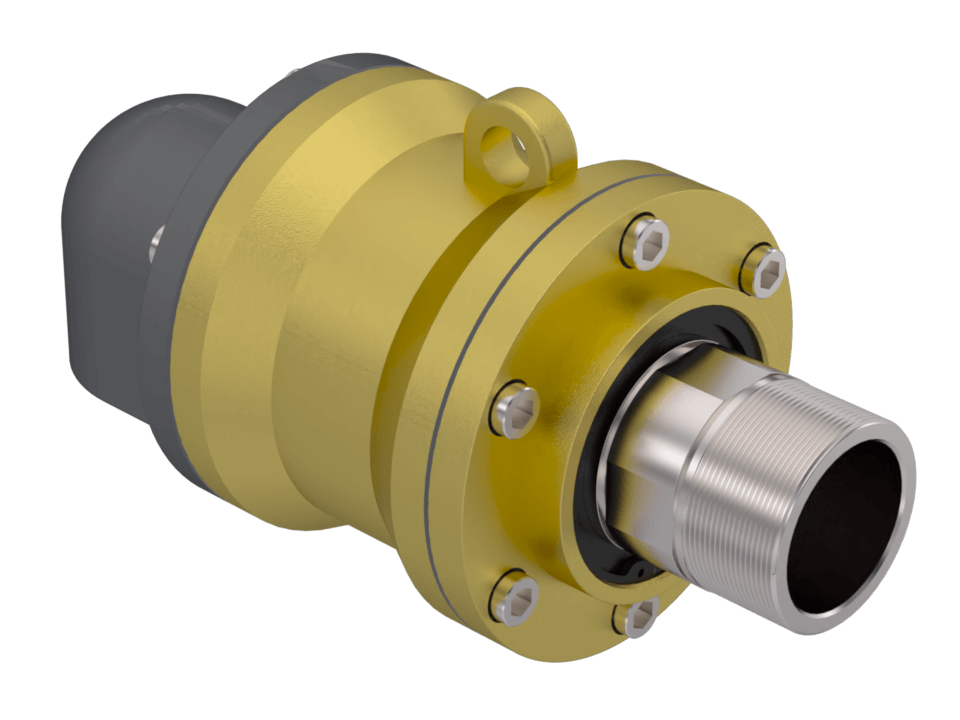

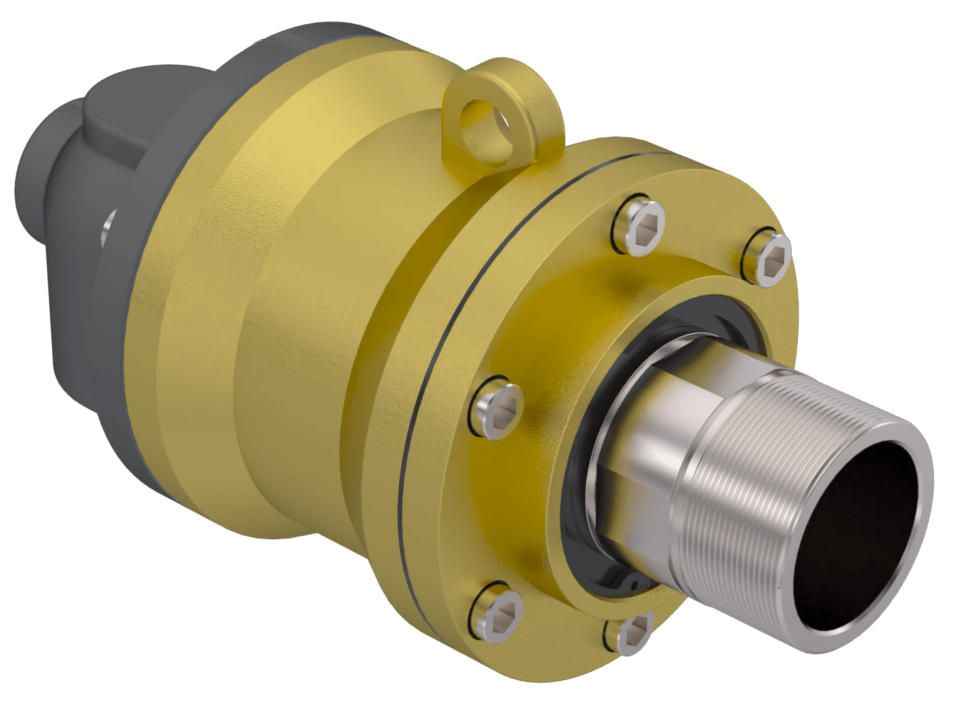

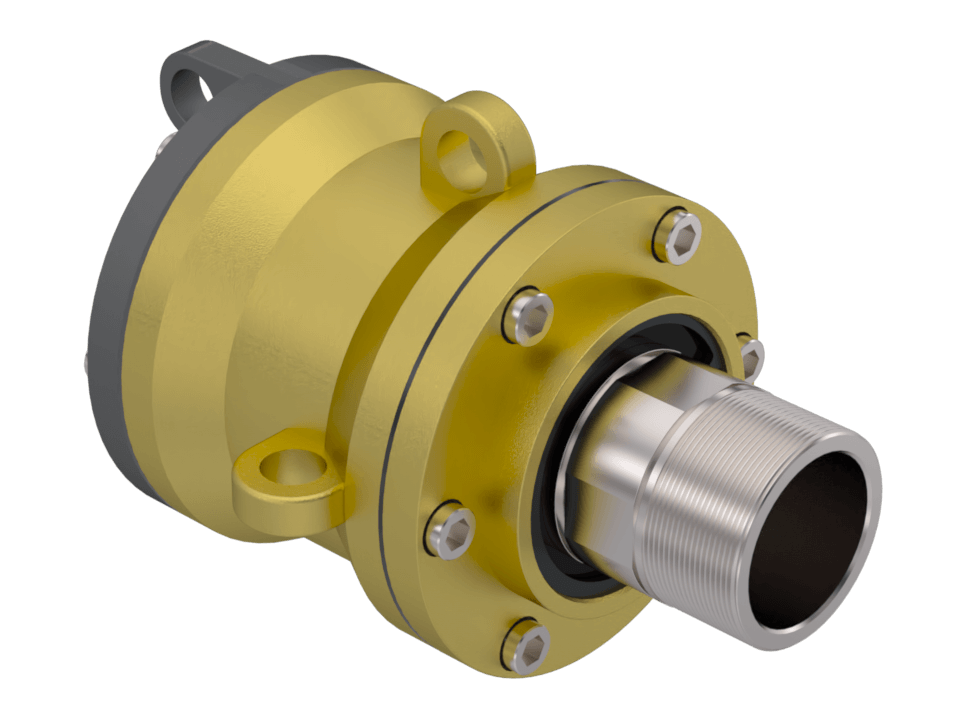

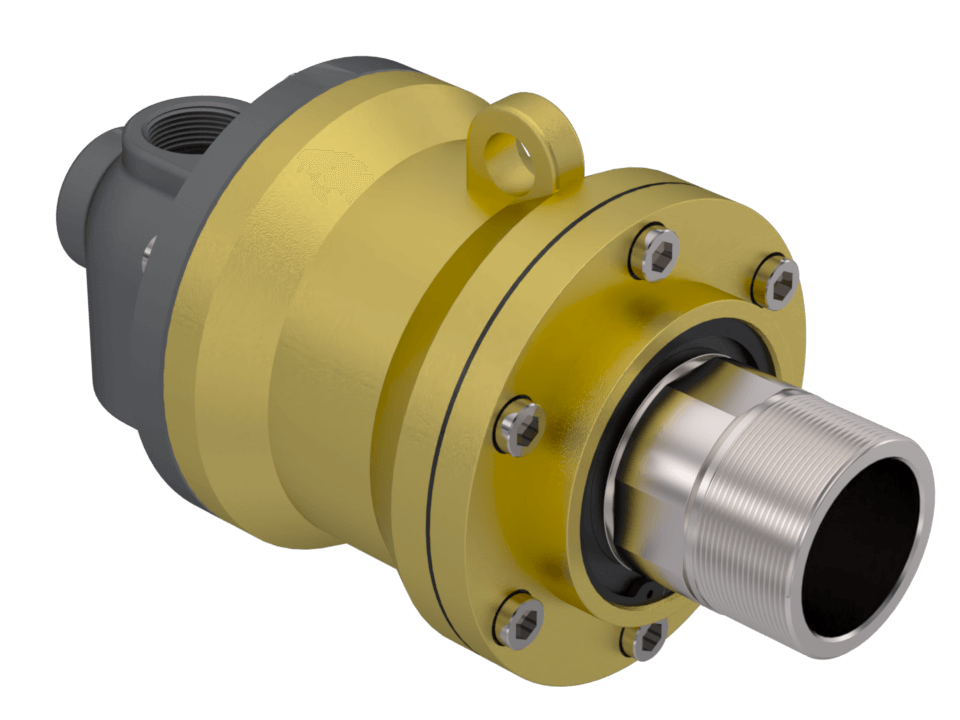

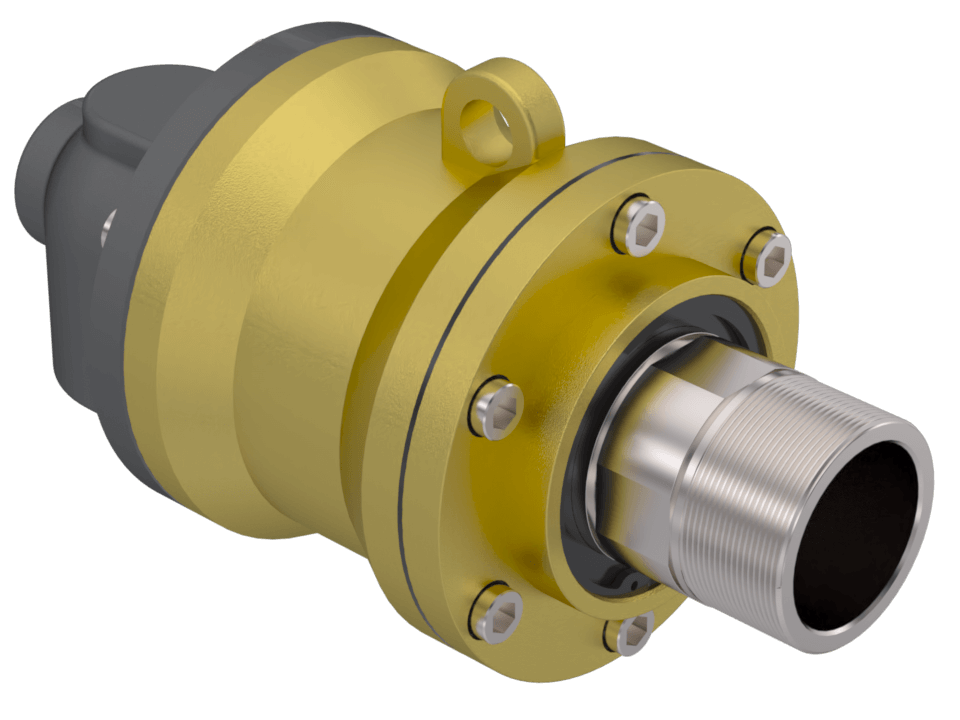

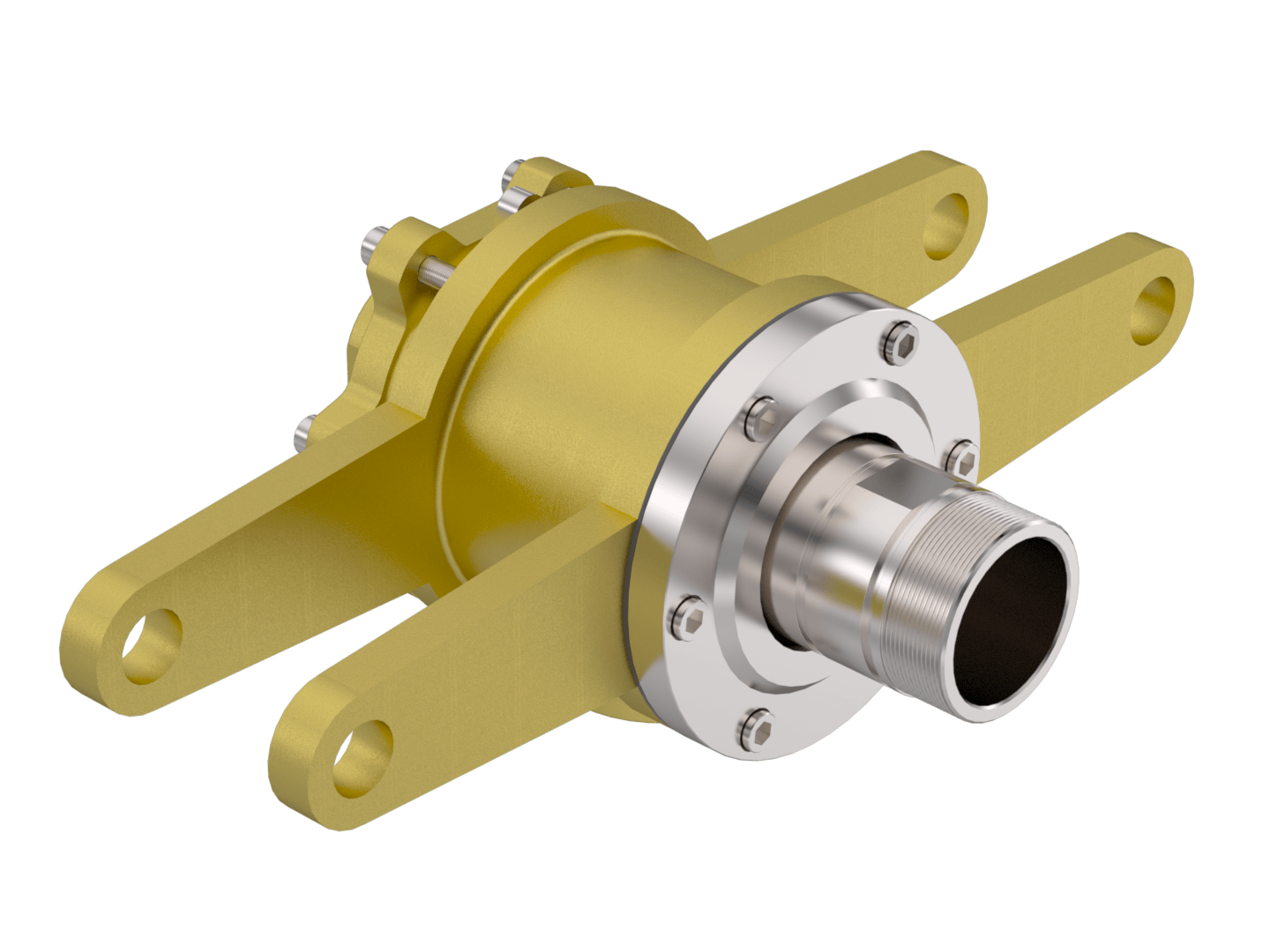

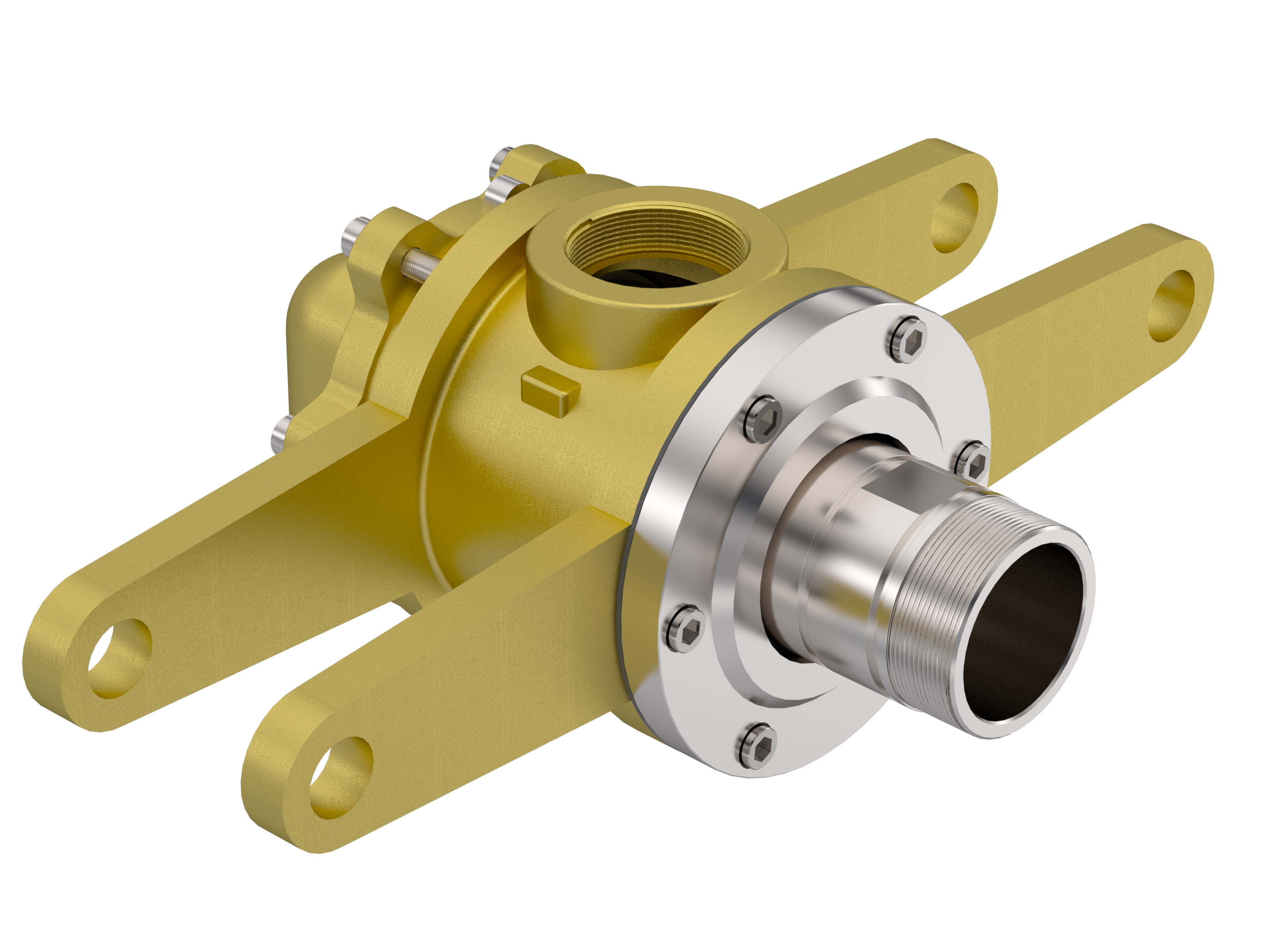

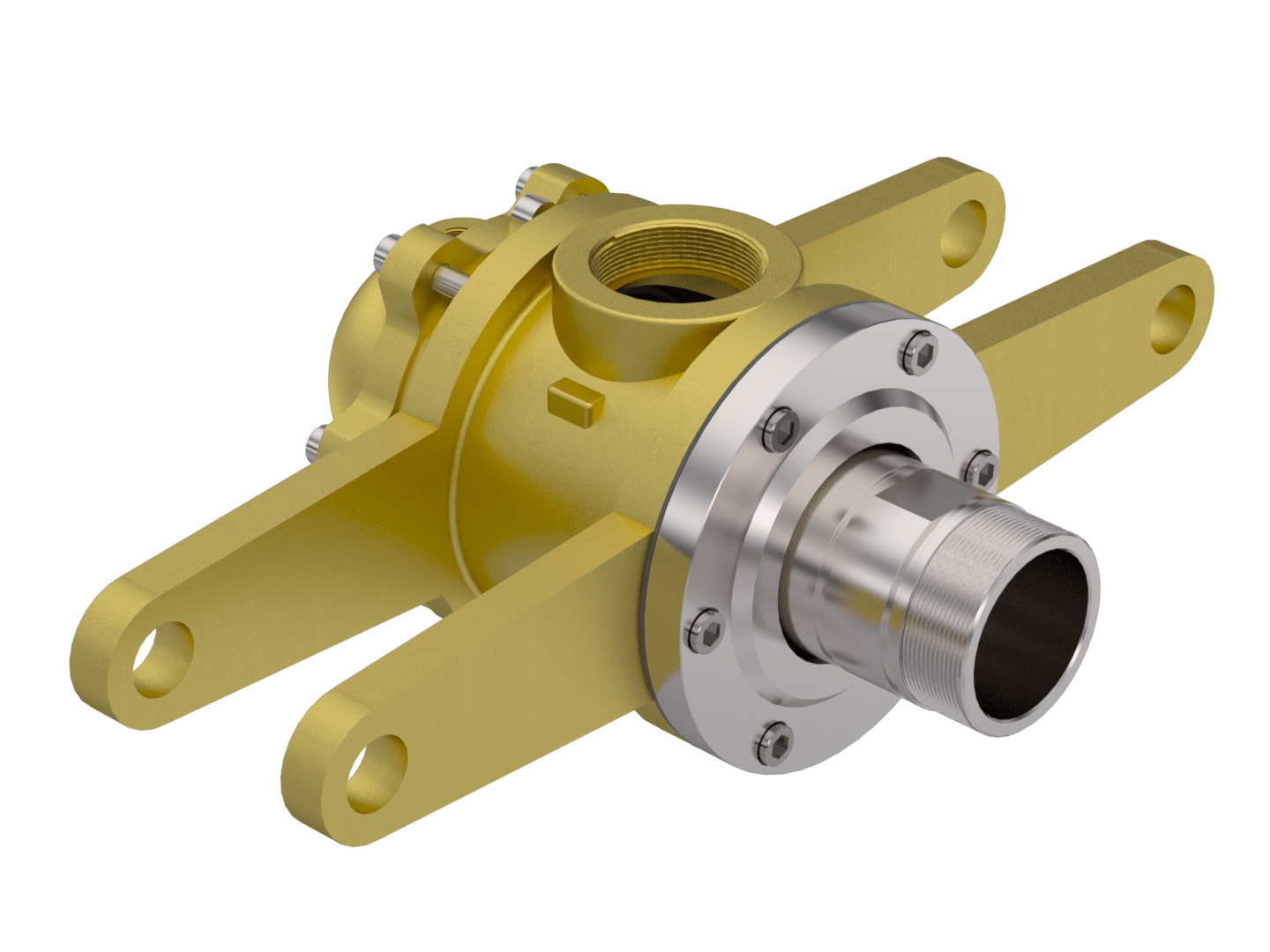

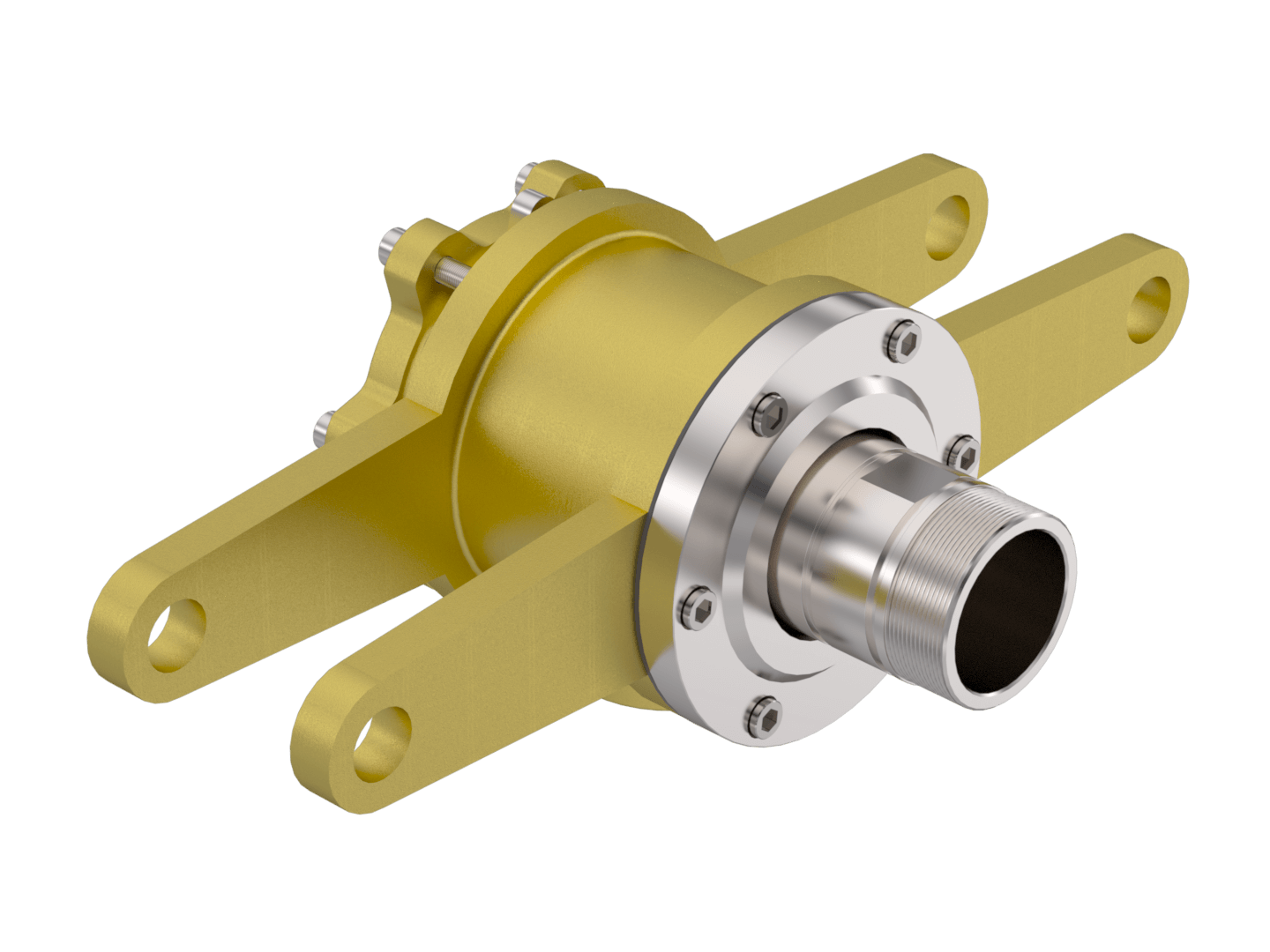

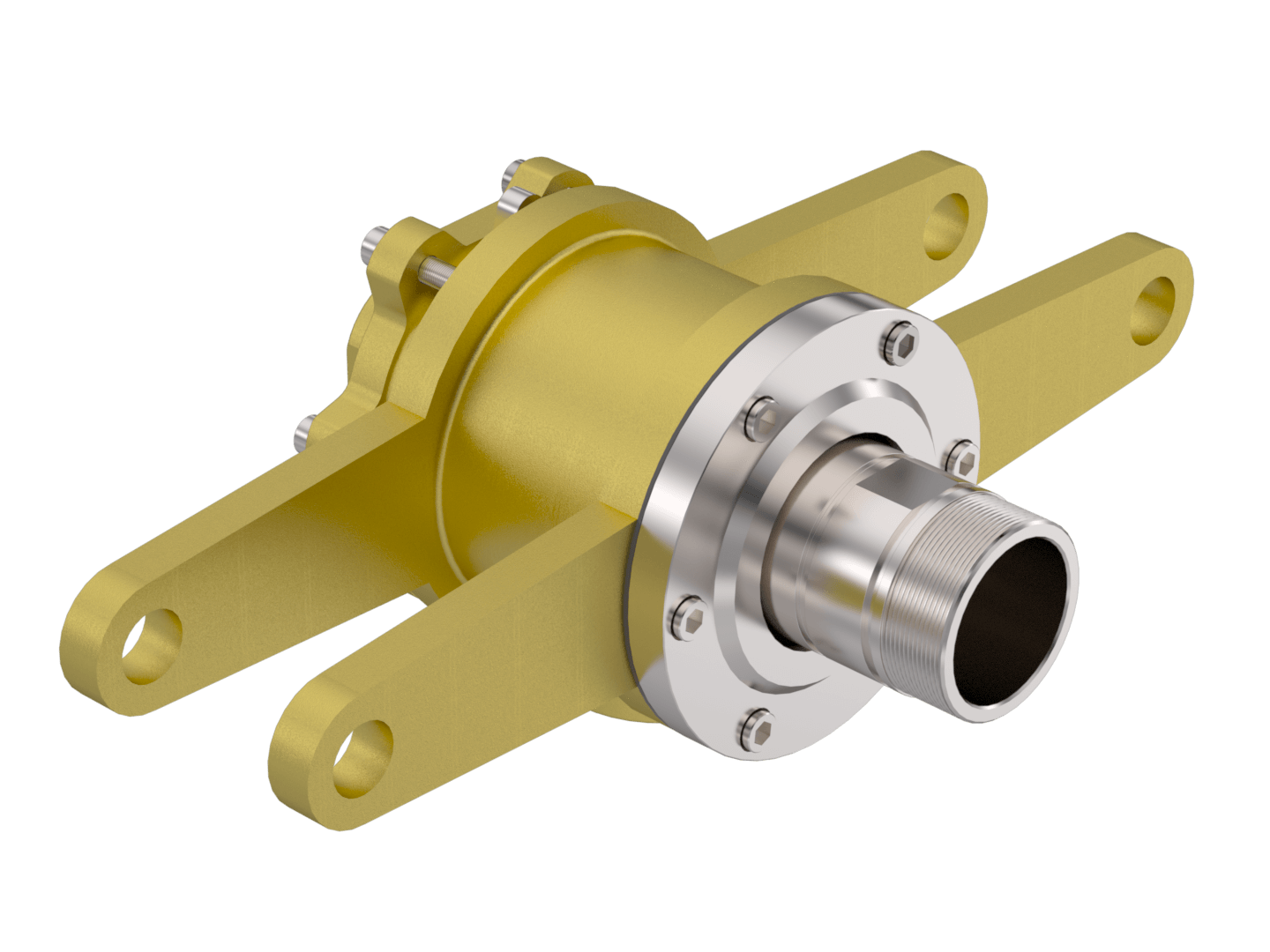

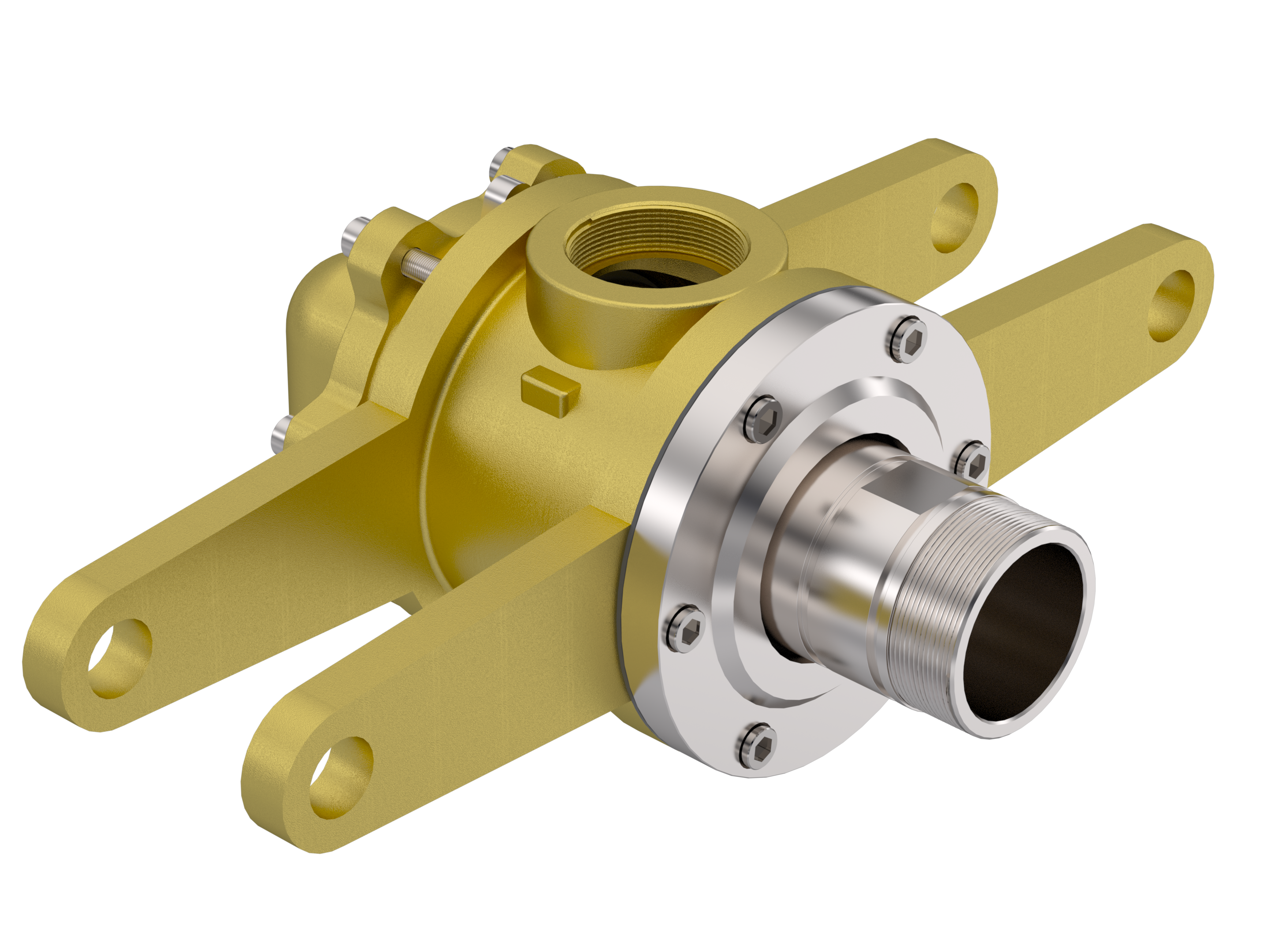

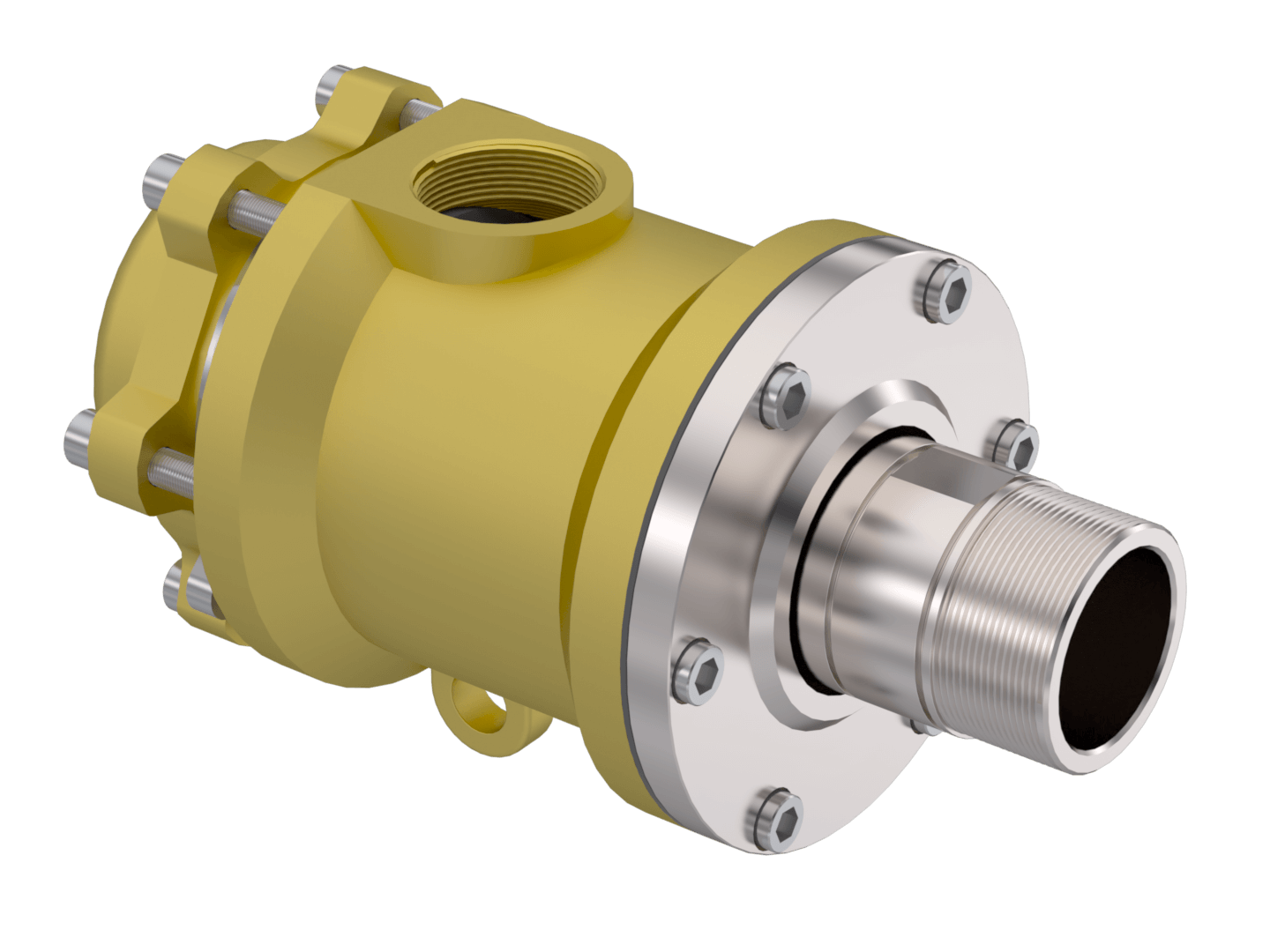

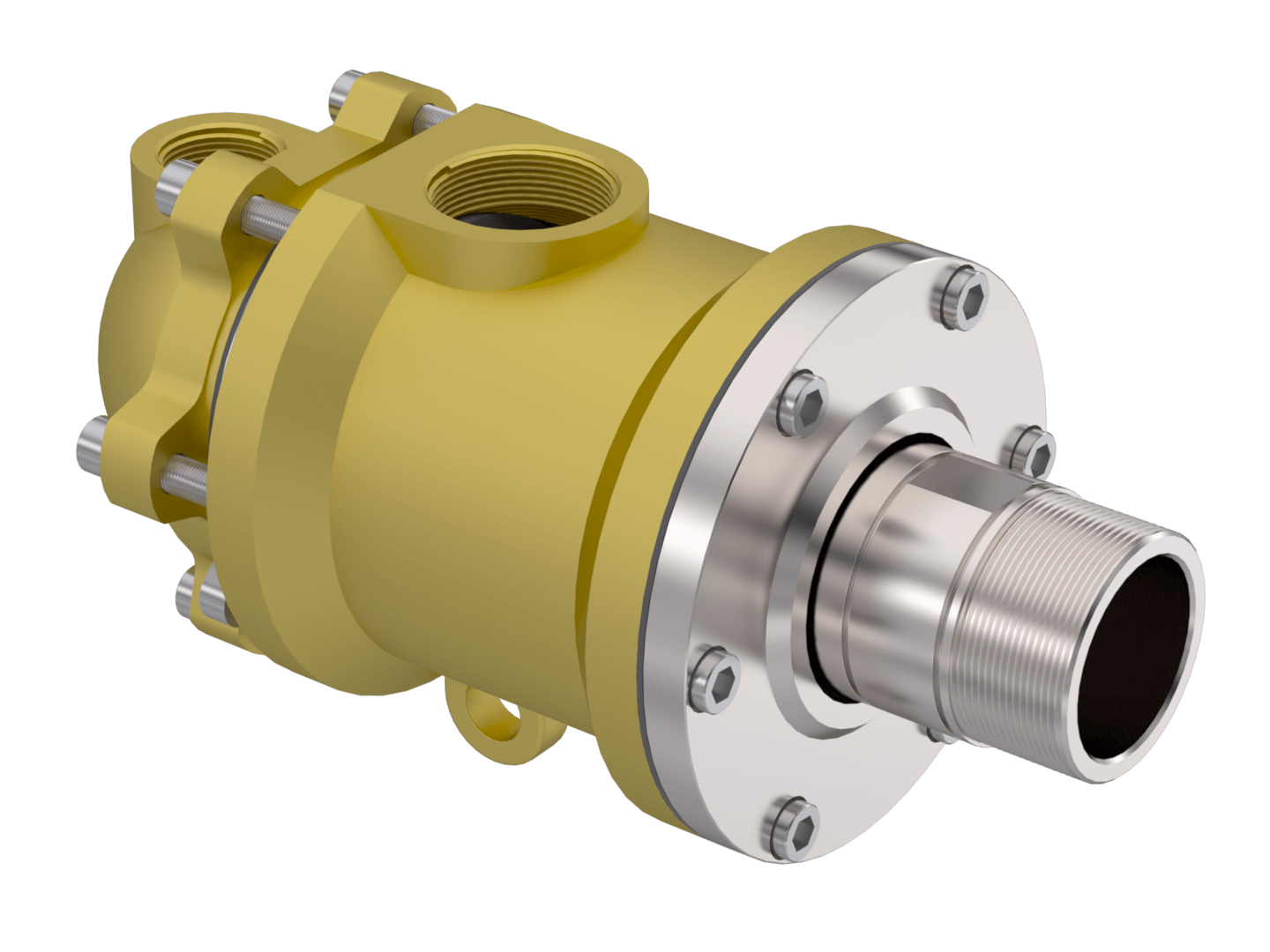

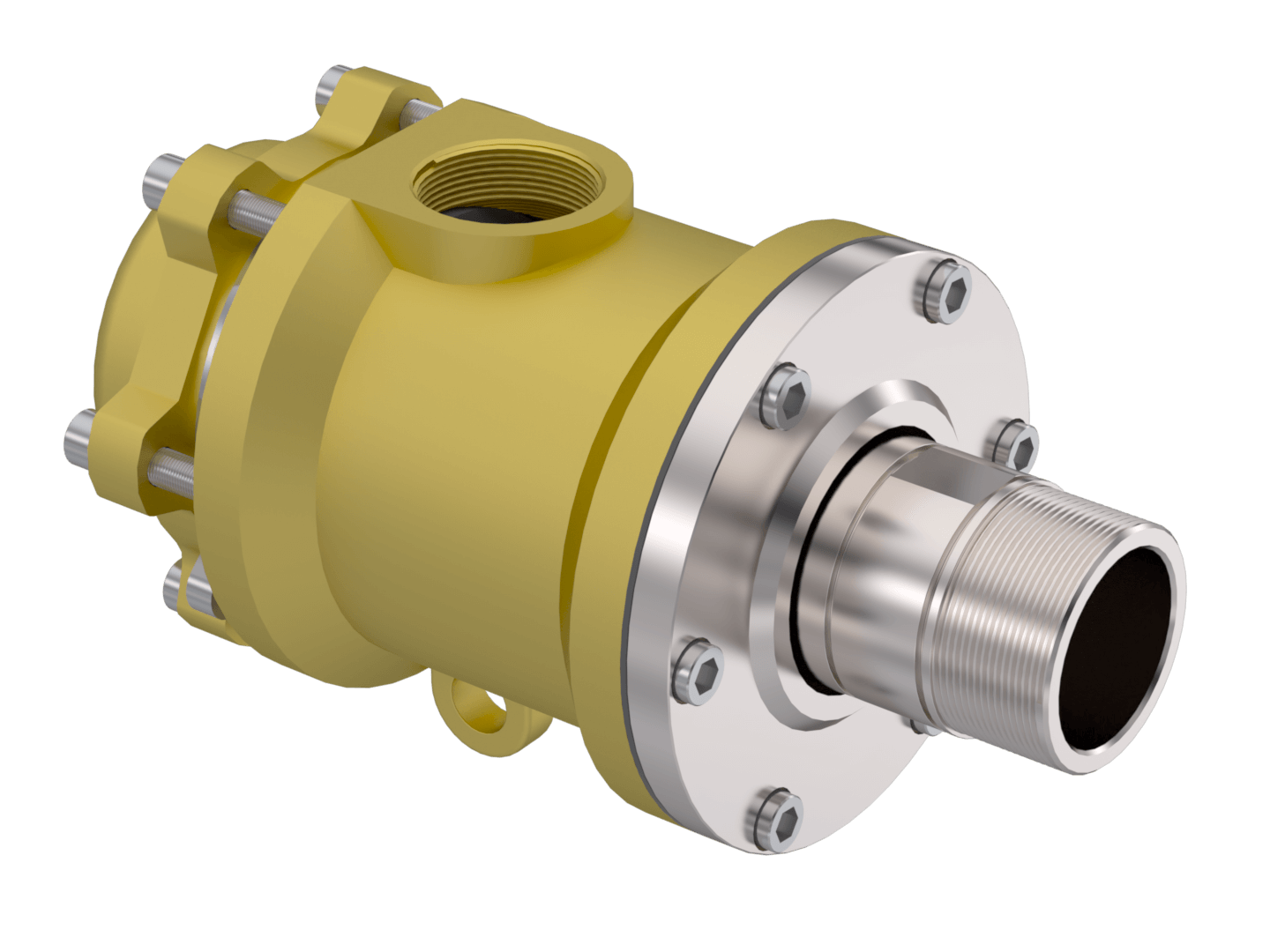

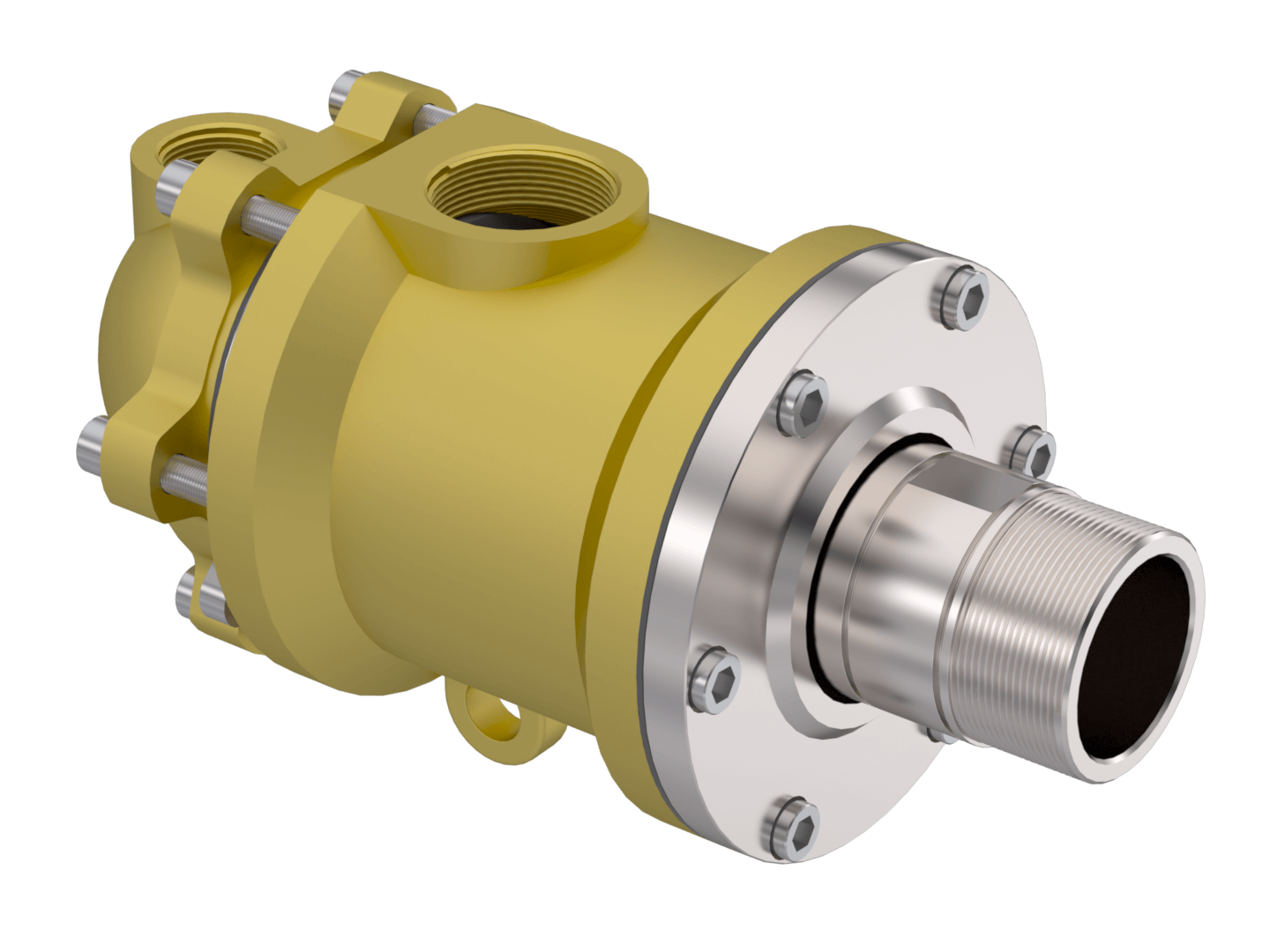

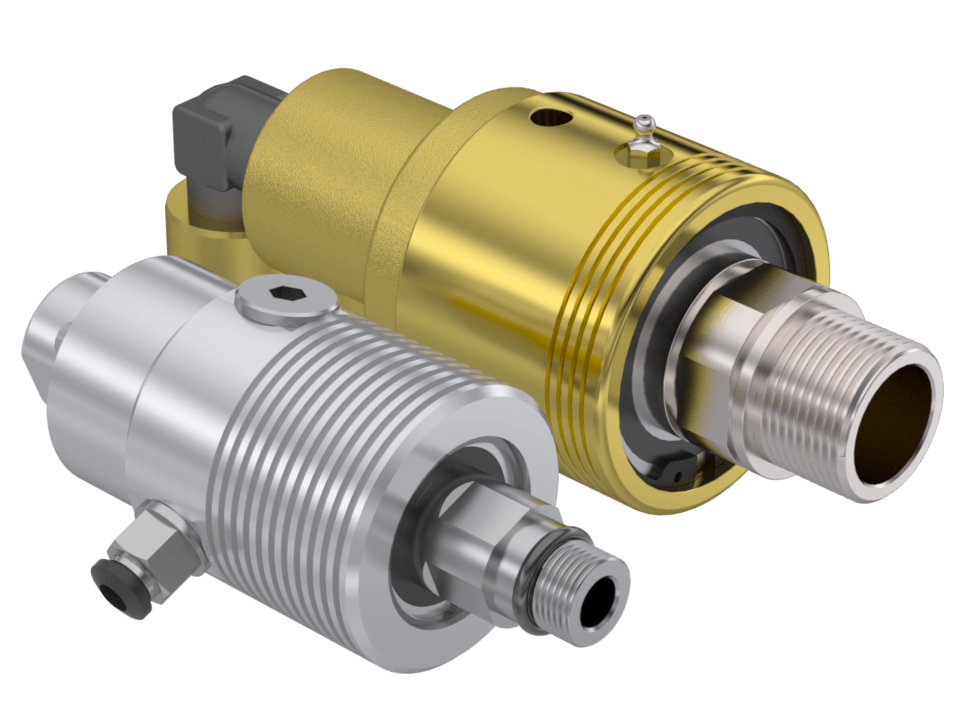

Rotary joints are mechanical sealing components used to transfer fluids from a stationary source into rotating cylinders of machinery. Rotary joints enable transfer of the fluids used to heat and cool.

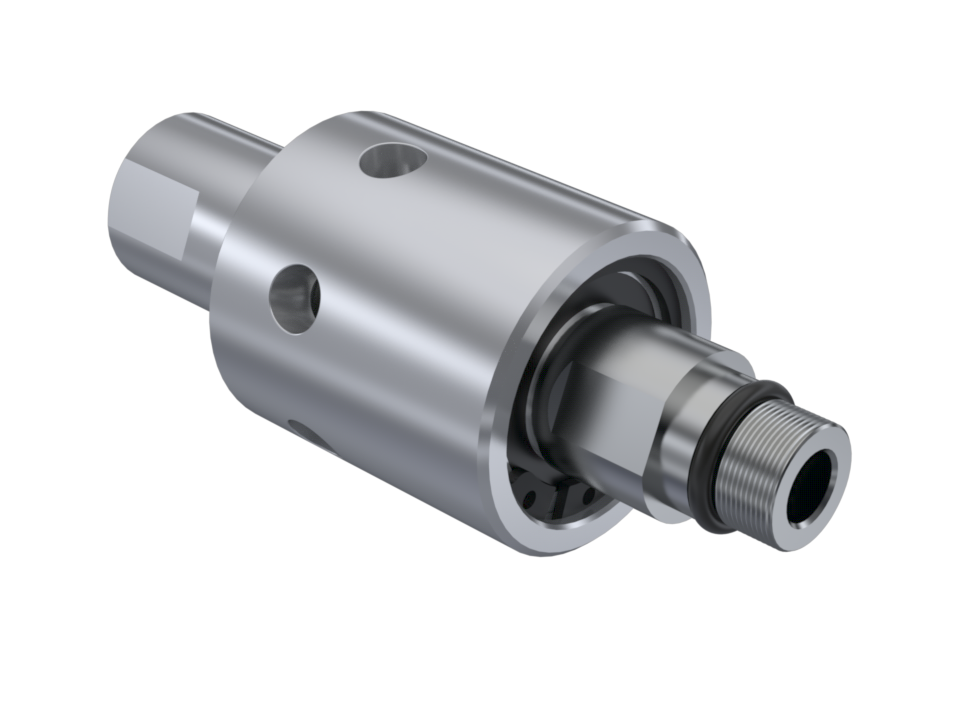

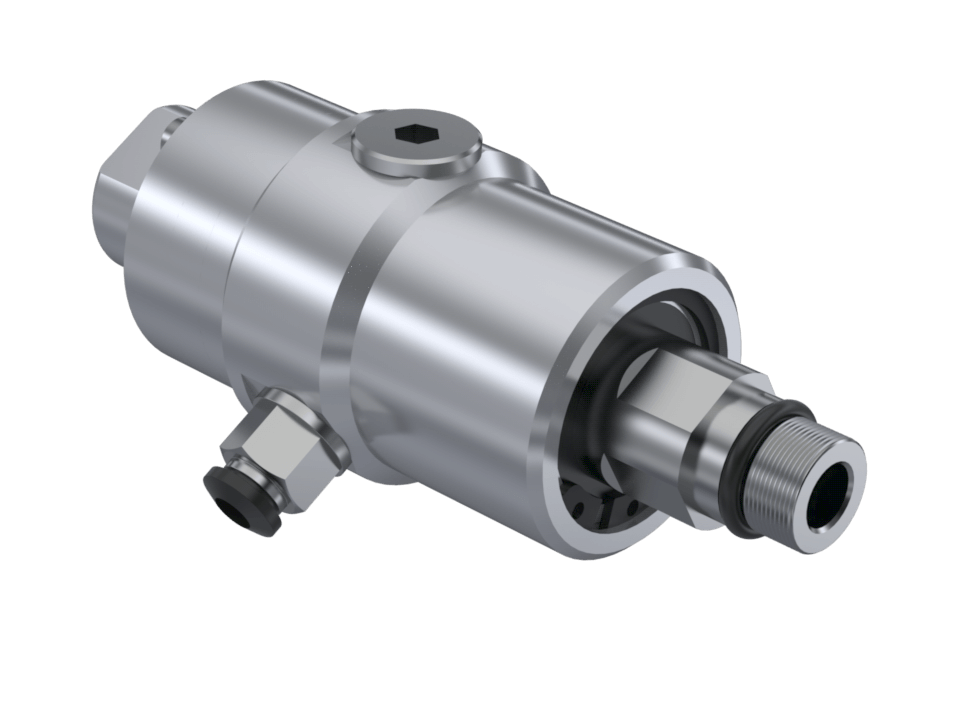

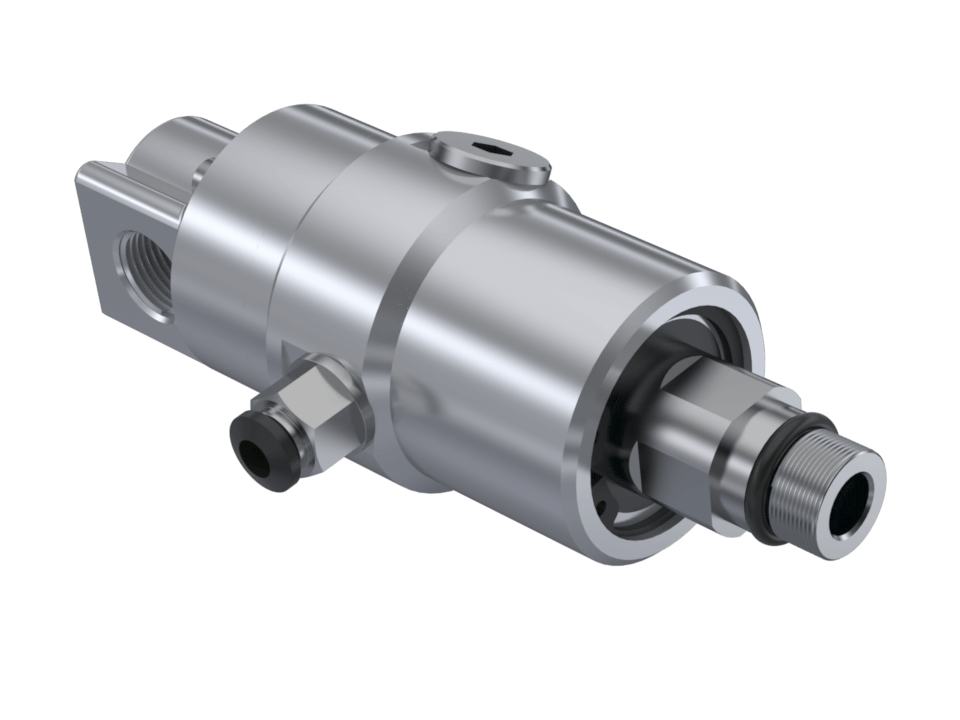

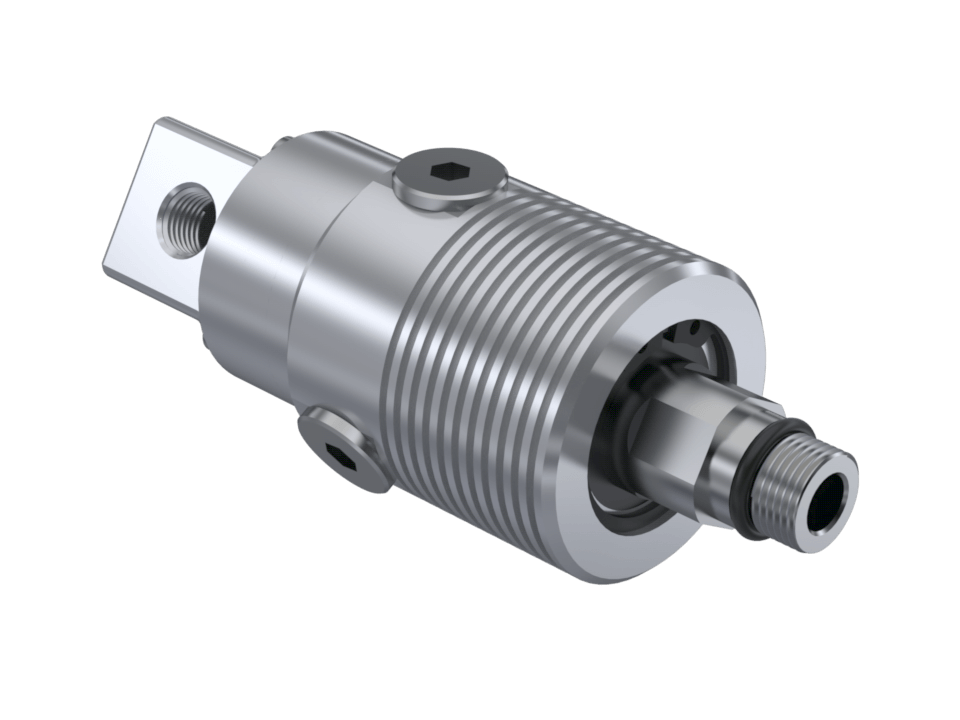

All models of

Rotary Joints

You may choose model and types according to your needs;

Explore by Media Type

All Series

Rotary Joints

Lubrication

All Rototech rotary joints are lubricated with bearings, tested and packaged cleanly. However, these headings should be lubricated in the factory, machine operating conditions and maintenance periods. It is important please use high-quality oil for lubricating.