We are manufacturing Rotary, Swivel and Multi-port joints for water, steam, hot oil, coolant, hydraulic oil and chemical Fluid Transfer Mechanisms.

ROTOTECH MAKİNA SAN.VE DIŞ.TİC.LTD.ŞTİ. which was founded in 2001, became a company renowned worldwide in the field of design and manufacturing of rotary joints, swivel joints, syphon systems and loading arms within a short span of time.

Products are used in various different industries including steel, textile, paper, food, chemistry, petrochemistry, aluminium, automotive, pharmaceuticals, construction materials, canned foods, cement, construction equipment, beverages and food, floor and wall coverings, leather sector, wood, machine tools, mining, petroleum, plastic, printing, etc.

Our company has developed a manner of work focused on customers’ demands by giving particular importance to customer satisfaction. We offer quick and economical solutions for standard and custom manufacturing practices.

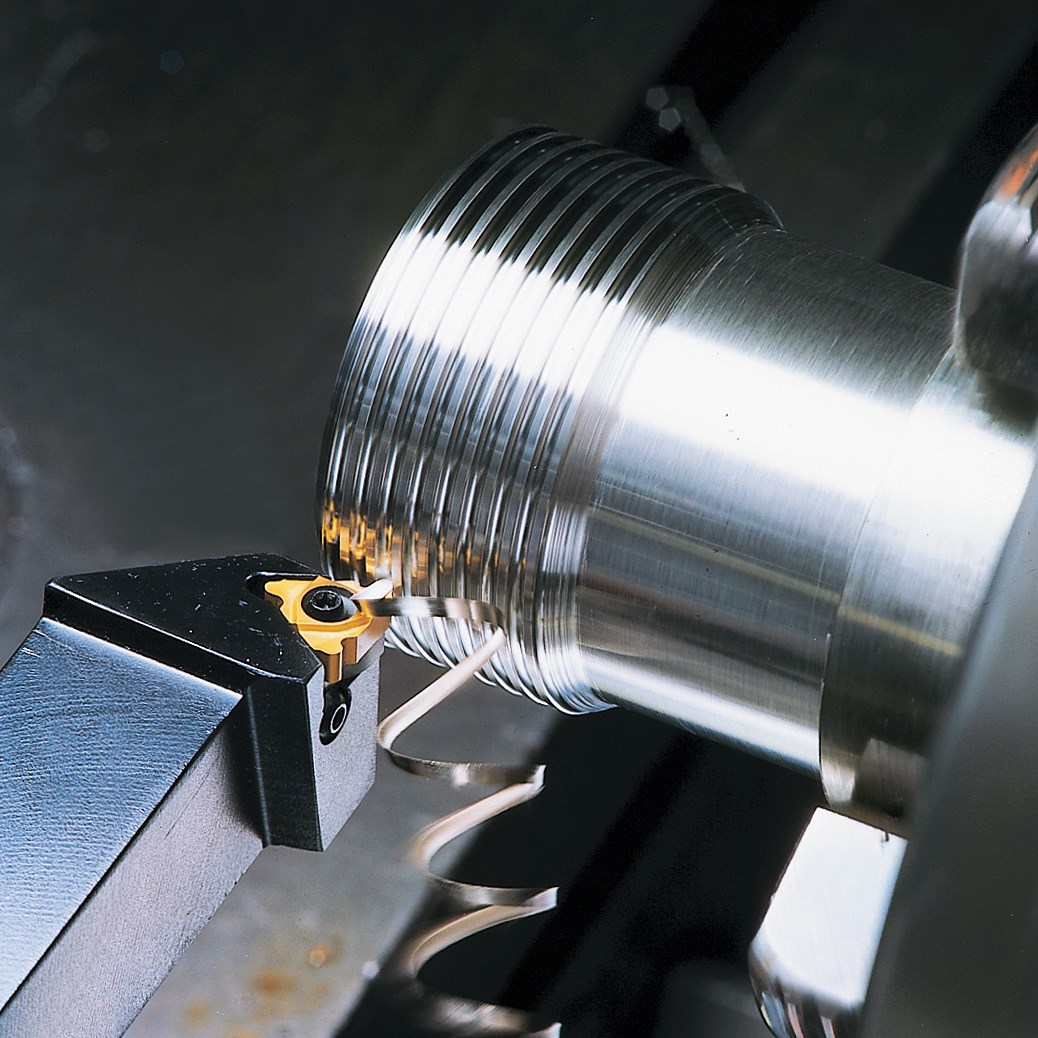

Up-to-date software and state of the art technologies such as CNC machinery are used to ensure measurement accuracy. Rotary unions are also manufactured upon demand for customary applications. Furthermore, we give special importance to research & development activities.

ROTOTECH gives special importance to quality control. From start to completion, every project undertaken are closely monitored to ensure its smooth progress.

Mission

Vision

Production Technology

Our understanding of production based on current scientific knowledge and data causes us to provide development on sealing technologies. According to this, our production process goes through three main stages related to standard or special orders;

CAD systems used during manufacturing, various axis CNC machines, special mounting and test equipment ensure precise dimensioning and tolerances; swivel couplings are manufactured in a short time for special applications.

Quality control processes start at the raw material input, continue throughout the whole production and end with individual control before the finished product is shipped. After-sales quality services continue, close contact with users and products are developed in line with the information received.

Our Milestones